Page 128 - ELT_15th July 2020_Vol 373_Part 2

P. 128

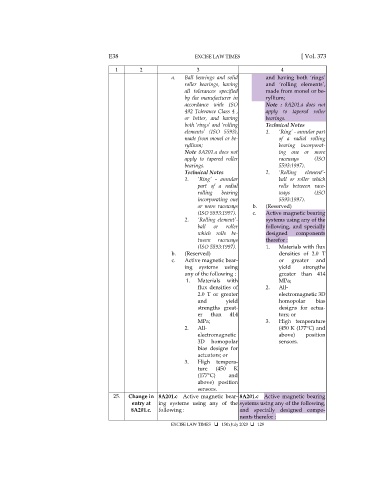

E38 EXCISE LAW TIMES [ Vol. 373

1 2 3 4

a. Ball bearings and solid and having both ‘rings’

roller bearings, having and ‘rolling elements’,

all tolerances specified made from monel or be-

by the manufacturer in ryllium;

accordance with ISO Note : 8A201.a does not

492 Tolerance Class 4 , apply to tapered roller

or better, and having bearings.

both ‘rings’ and ‘rolling Technical Notes

elements’ (ISO 5593), 1. ‘Ring’ - annular part

made from monel or be- of a radial rolling

ryllium; bearing incorporat-

Note 8A201.a does not ing one or more

apply to tapered roller raceways (ISO

bearings. 5593:1997).

Technical Notes 2. ‘Rolling element’-

1. ‘Ring’ - annular ball or roller which

part of a radial rolls between race-

rolling bearing ways (ISO

incorporating one 5593:1997).

or more raceways b. (Reserved)

(ISO 5593:1997). c. Active magnetic bearing

2. ‘Rolling element’- systems using any of the

ball or roller following, and specially

which rolls be- designed components

tween raceways therefor :

(ISO 5593:1997). 1. Materials with flux

b. (Reserved) densities of 2.0 T

c. Active magnetic bear- or greater and

ing systems using yield strengths

any of the following : greater than 414

1. Materials with MPa;

flux densities of 2. All-

2.0 T or greater electromagnetic 3D

and yield homopolar bias

strengths great- designs for actua-

er than 414 tors; or

MPa; 3. High temperature

2. All- (450 K (177°C) and

electromagnetic above) position

3D homopolar sensors.

bias designs for

actuators; or

3. High tempera-

ture (450 K

(177°C) and

above) position

sensors.

25. Change in 8A201.c Active magnetic bear- 8A201.c Active magnetic bearing

entry at ing systems using any of the systems using any of the following,

8A201.c. following : and specially designed compo-

nents therefor :

EXCISE LAW TIMES 15th July 2020 128